Shaping Station

“Roundabout”

The shaping station traditionally could be a ton, on to which we put a steel-ring so we can fix a shell for shaping it with different hammers. The problem which occurs is: one is basically dancing arround the ton during the heavy work with the airhammer. So some sort of rotary system should help.

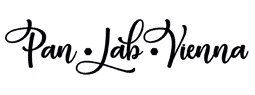

This is how our shaping station looks like.

With engine or without: in both cases it turned out to be very helpful.

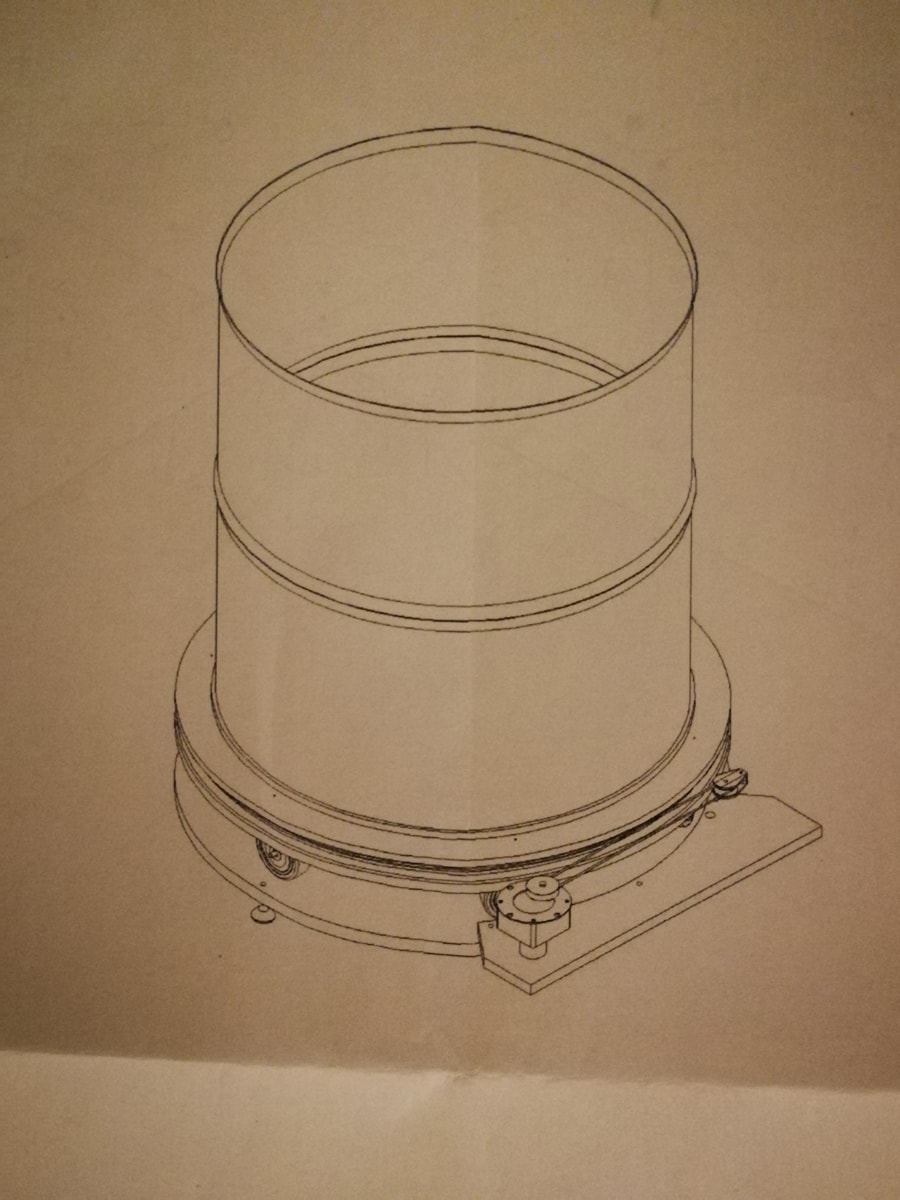

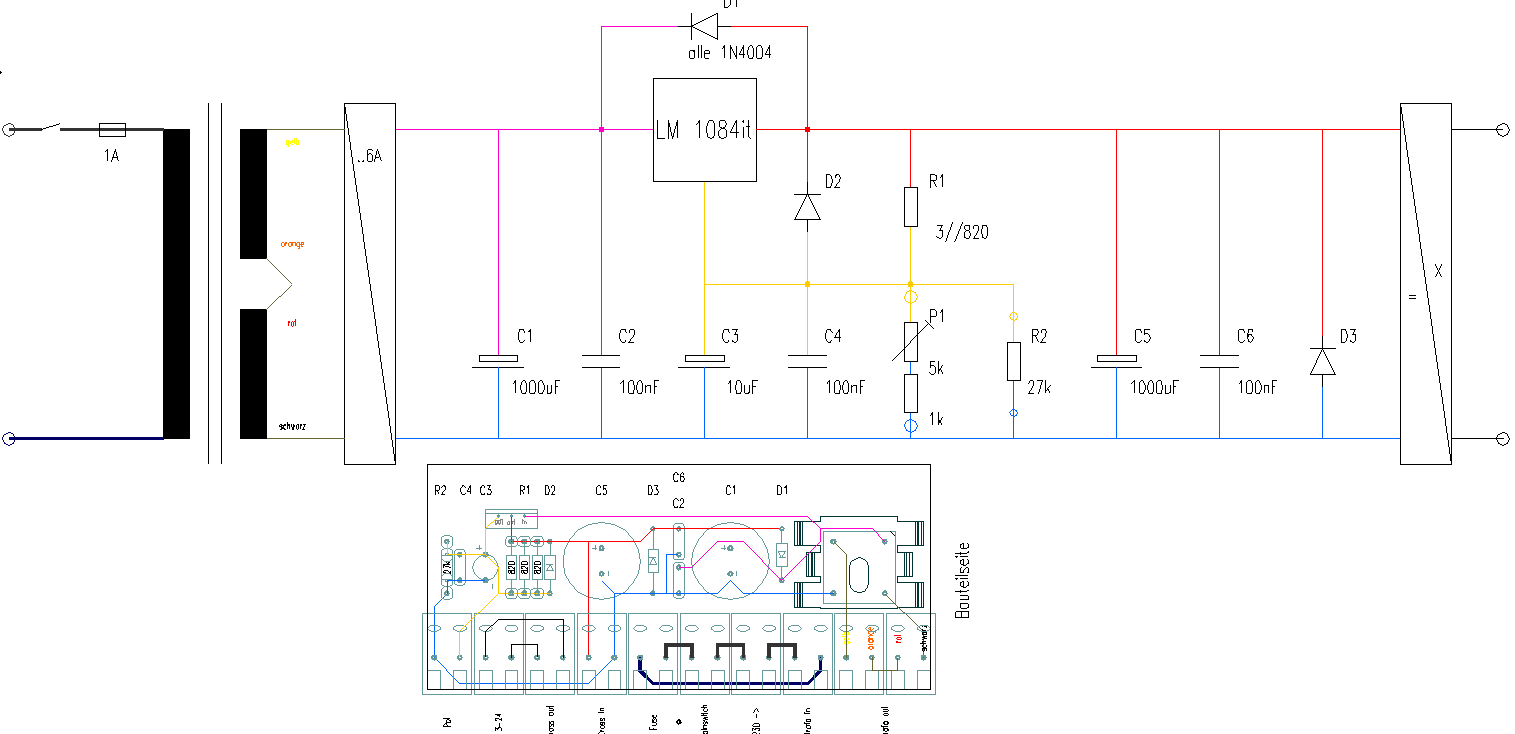

The Roundabout-Engine has a direction switch and an analog wheel for adjusting the speed.

The Axle bearing part was done very professionally, the spinning goes very smoothly. So far we found it the savest way – for the health of the spine- for shaping the shells.

The brown material for the spinning part we call “Siebdruckplatte” and the cost for this was very little (some sellers might also cut it for you with no extra cost) and it is not something difficult to build if you make your calculations about your ton.

PS. Happy Detail: The PLV engine was put together by Martin Grabner with only existing stuff and “trash” from arround the neighbourhood.

Other PLV Workstations and tools...

Tuning Hammer Think Thank

working on that….

PLV Finetuning Chair: “Fetsel”

Finetuning Pans with a happy spine. Ergonomic working with 3 optional sitting positions…

PLV Finetuning Station „Fetsi“

experimental finetuning at PAN LAB

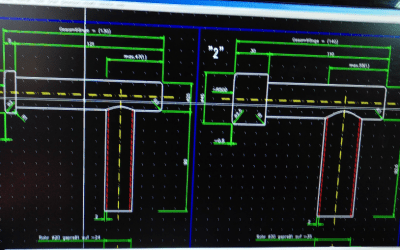

PLV Tuningstation: “Tunerbell”

Inspired by the Shellopan tuningstation, which is not only solid and stable but also nicely rotatable…